Packaging cutting machine

The electric vibrating knife gun head has strong power and high vibration frequency; the whole machine adopts high-precision transmission mechanism, which has faster response speed, higher positioning accuracy and more stable performance; the servo motor is used to control the up and down movement o

Product introduction

Functional features

High speed motion control system

With independent intellectual property rights of high-end six axis high speed motion control system, system upgrade and maintenance is not controlled by a third party, convenient maintenance, high reliability, low cost, because of the control in hand, can be convenient for the user's personalized needs custom-made special program and for remote upgrade.

Independent movement control CARDS

Controller from previous computer motherboard card era, upgraded to a high performance integrated circuit controller, can be connected with any ordinary computer (notebook), completely ruled out because of the computer link before failure is caused by the cutting equipment paralysis.

Modular structure design

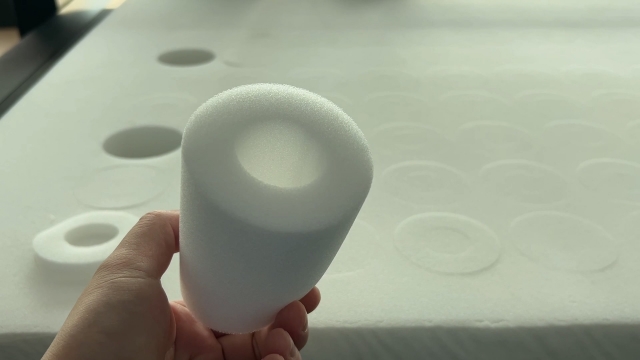

It adopts the internationally advanced replaceable tool head design concept. The tool head is not fixed and welded integrated. It can be easily replaced and equipped with tool heads with different functions according to actual work needs and business scope expansion. It solves the problem that fixed integrated tool heads cannot be upgraded due to new demands. Compared with pneumatic heads, it also solves the problem that pneumatic pressure cannot be kept constant due to fluctuations in temperature and time.

Any combination of functions

In addition to the traditional cutting tools such as vibration cutter, drag cutter, half cutter and drawing pen, tool-type milling tools can also be selected. Depending on the different needs of different materials, functions such as writing and drawing lines, dotted line cutting, half-cut cutting, and full-cut cutting can be realized. Various flexible materials such as Chevron board, KT board, adhesive board, corrugated paper, gray board, honeycomb board, white cardboard, kraft paper, red cardboard, EPE foam, etc. can be cut.

Convenient network transmission

It uses a network interface with fast transmission speed and long distance. One computer can control multiple devices (the computer can be replaced at will). Compared with the old serial port, parallel port, and PCI interface, it is more stable and convenient.

Powerful and efficient suction

The energy-efficient partitioned vacuum adsorption system ensures that the material can be optimally fixed. The machine table is made of an integrated ground aluminum honeycomb panel, which has good air permeability, high precision, durability and is not easy to deform.

Work safety

Equipped with a safety device (the machine will automatically stop if a person's hand enters the infrared range).

High efficiency and labor saving

Fast speed 1500mm/s。

Flexible combination of tools

Flexible tool system compatible with all DN5 series products.

Production efficiency

Can cut paper, leather, cloth, PVC, carbon fiber, cotton and other non-metallic flexible materials<br />Unparalleled production efficiency comes from the application of intelligent control technology, powerful system components and advanced tooling. Perfect coordination, so the system components guarantee the optimization of the production process.

Intelligence brings high performance

High-performance cutter controller with high-performance servo motor, intelligent, detail-optimized cutting technology and precise, maintenance-free drive. With excellent cutting performance, low operating costs and easy integration into production processes.

Efficient material fixing

The energy-efficient and adjustable vacuum system ensures that the material is optimally fixed. You no longer have to worry about the material moving during processing. In addition to ensuring the cutting quality, you will undoubtedly enjoy lower energy consumption.

Front large electric box

Scientific and concise wiring system and chassis circuit design, stable and safe; equipped with all tool interfaces, supporting the subsequent addition and upgrade of all tools; easier installation, repair and maintenance.

Safety protection system

The precise beam sensing system and the emergency stop switch to prevent misoperation ensure production safety in all aspects.

Double rod cylinder

It adopts double-rod cylinder, with uniform and high pressure, stable material pulling for a long time and not easy to be damaged.

DNCUT Editing software

Powerful editing CAD design software, the perfect combination of Montana, CDR, AI, ONYX, CALDERA, Printfactory software; Database support bar code read die cutter line, improve the work efficiency, reduce the error rate.

Technical parameters

|

Model |

DN5-S |

|

Working area(L*W) |

1400*1000mm | 1800*1300mm | 2500*1600mm | 2500*1800mm | 3000*2000mm |

|

Overall-dimensions(L*W) |

2100*1700mm | 2500*2000mm | 3200*2300mm | 3200*2500mm | 3700*2700mm |

|

Special size |

Can be customized |

|

Tools |

EOT,UCT,KCT,UDT,POT,PRT,CTT1,VCT |

|

Safety device |

Physical anticollision structure + infrared induction anti-collision, ensure production safety |

|

Cutting thickness |

0.2-60mm(Can be customized) |

|

Cutting materials |

Honeycomb cardboard, corrugated paper, insulating board, grey board paper, white cardboard, film, composite materials, leather, cloth, plastic board, pearl cotton, heat preservation, sound insulation cotton, gaskets and other materials. |

|

Cutting speed |

≤1200mm/s(according to different cutting materials) |

|

Cutting accuracy |

±0.1mm |

|

Repeated accuracy |

≦0.05mm |

|

Cutting circular |

≧3mm diameter |

|

Positioning way |

CCD camera and Laser positioning |

|

Fixed mode |

Vacuum adsorption |

|

Transport interface |

Ethernet front-end ports |

|

Software format |

AI software, AutoCAD, CorelDRAW, and all of the box type design software can output directly, without conversion, and with automatic optimization |

|

Instruction system |

HP-GL compatible format |

|

Operation panel |

Multilingual LCD touch panel |

|

Transmission system |

High precision linear guide, precision gear rack transmission structure, servo motor and drive |

|

Voltage |

AC220V 380V ±10%,50HZ;Power 9kw |

|

Pump power |

7.5KW(default) |

|

Work environment |

Temperature:-10℃~40℃,Humidity:20%~80%RH |

|

Application industry |

Clothing, textiles, household, shoes, leather bags, sound insulation, sealing, automotive, aerospace, new energy, etc |

Solutions

Cutting machine is suitable for all walks of lifeContact us for more information

Service contract; Remote service; Customer service center; Training; Hardware upgrade; Component stock; Special task support; Upgrade/moving/renew; Service at production facility; Sample innovation & development